servo drive ,Double spindle cutting, Eight axis linkage

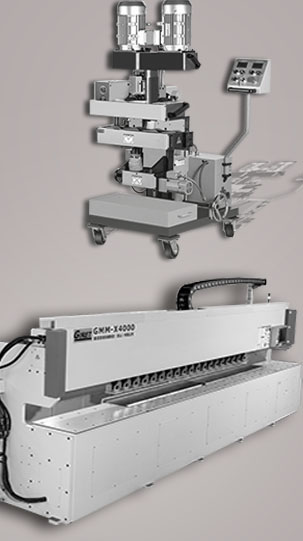

GMM-X3500 CNC edge milling machine:

This type of product is first machine of GIRET brand CNC milling machine GMM-X series. According to customer requirements, it has customized an effective processing stroke of 3500mm, independent upper and lower spindles for groove processing, and a high-precision groove machine that can process 0 degree milling and K-type groove operations. The processing speed reaches 0~1500mm/min, the accuracy is ±0.5 degree, and the straightness is ±0.5mm.

GMM-X3500 CNC edge milling machine technical parameters:

Power supply--------------------------------AC380V 50HZ or AC415V or AC380V

Total power----------------------------------28KW

Running Power----------------------------------18KW

Spindle Power----------------------------------2*5.5KW

Touch screen----------------------------------15寸

Control system---------------------------------GIRET-V1.0

GMM-X3500 CNC edge milling machine processing capacity:

Bevel angle: Abolve bevel: angle..0~85° adjustable, 90 degree support

Under bevel angle: 0~60° adjustable

Bevel width: Ablve bevel width: 0~100mm 90 degree=0~40mm

Under bevel width 0~100mm

Processing bevel speed:0~2000mm/min

Processing plate thicknessL 5~80mm

Plate length>150mm

Processing length: 3500mm

Bevel type: V/K/Y/X/L/J/U

HMI

GMM-X3500 CNC edge milling machine feature:

1. PLC system control makes the system more stable;

2. HMI human-computer interaction interface, touch screen operation, intelligent beveling machine, which can be operated by ordinary workers;

3. Safer operation: the control panel is low voltage, and the normal operation is far away from moving components;

4. The uphill angle is adjusted steplessly at 0~85 degrees, and the downhill angle is adjusted steplessly at 0~60 degrees;

5. The accuracy of groove angle shall reach ± 0.5 degree;

6. The straightness of the processing groove shall reach ± 0.5mm accuracy;

7. Equipped with electric cooling system;

8. Equipped with automatic chip removal system, which is cleaner;

9. More environmental protection, no need for cutting fluid, low noise;

10. Processing data can be stored and called at any time;

11. The human-computer interface diagram is intuitive;

12. Misoperation prevention system, automatic shielding of overrun range;

13. First Construction starts automatic groove program;

14. Manual calculation of processing data is not required for groove processing, and the system automatically cuts by layers;

15. It supports two language versions, Chinese/English by default, and the language can be customized according to customer needs;

16. Cold cutting, no oxidation deformation on the surface;

17. Real time monitoring of system input and output status;

18. Support remote rescue to make users feel more comfortable;

19. The system independently adjusts the upper and lower groove angles. The system automatically assigns the spindle according to the customer's input data.

From: tapmelater.com